-

UK first electrification system for rail freight terminals supports path to net zero rail

-

Roll-in roll-out electric freight trains could reduce delays to passenger services

-

Innovative moveable system overcomes conflict between loading freight trains and overhead electrical equipment

A rail freight terminal in Northamptonshire has become the first in the UK to demonstrate an innovative overhead electrification system, which could spell the end for diesel on electrified rail routes and boost the industry’s net zero ambitions.

The Decarbonisation & Electrification of Freight Terminals (DEFT) project, funded by the Department for Transport and Innovate UK, has seen project partners Furrer+Frey GB, Tarmac and GB Railfreight demonstrate a new way of decarbonising rail and lessen freight’s impact on passenger journeys.

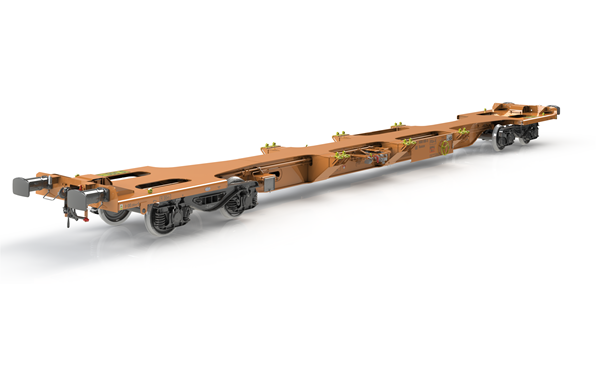

Freight trains are typically loaded and unloaded from above, preventing the use of the high voltage overhead cables used on mainline railways. As such, they still rely on diesel to move in and out of terminals and passengers can be held up by slower diesel freight trains on mainlines, or those waiting to be moved into a depot by a shunter.

Engineers from Furrer+Frey GB designed a Moveable Overhead Conductor system where overhead equipment supplying electricity to the locomotives can safely move away once the train is in place and return when the train needs to move again.

Furrer+Frey’s innovative system is being trialled at an aggregate facility – run by one of world’s leading construction materials businesses, Tarmac – in Wellingborough, in partnership with GB Railfreight.

The facility is adjacent to the Midland Mainline, which is currently being electrified and upgraded by Network Rail as part of the Government’s Integrated Rail Plan, to increase capacity for passengers and freight trains.

If successful, the moveable overhead system could go on to be deployed at other freight terminals across the UK and support the full decarbonisation of Britain’s railways.

Rail Minister Wendy Morton said:

“It is fantastic to see winners of our First Of A Kind competition getting out there and helping transform the railways for the better.

“Making rail freight even more environmentally friendly helps us leap forward in our plans to build back greener and make the whole UK net zero by 2050.”

Noel Dolphin, Head of UK projects at Furrer+Frey GB, said:

“The electrification of freight terminals is the biggest technological hurdle to net zero rail freight and we have just overcome it. The demonstrator shows how we can plug freight yards into electrified rail lines and operate them safely and efficiently with the locomotives we already have – meaning greener, cleaner and better journeys.

“This moveable conductor system means trains pull in on electricity, disconnect from it to safely load and unload, then reconnect to travel on.

“I’m proud of our team and partners for getting us to this milestone moment today showing a greener future for the industry.”

Chris Swan, head of rail at Tarmac, said:

“Decarbonising transport has been highlighted as one of the key areas in which we can help achieve net zero across the construction industry.

“Supporting this exciting project is just the latest step in the ongoing development of our rail freight capabilities, which forms part of Tarmac’s wider commitment to reducing CO2 across the whole business.

“We’re always keen to explore new initiatives and innovations that can help us move materials to the right place at the right time more efficiently and sustainably.”

John Smith, CEO GB Railfreight, said:

“Rail freight is already a greener alternative to moving goods by road but innovations like the Moveable Overhead Conductor System, and electrification more broadly, will allow us to go even further.

“At the same time as combatting climate change, they also bolster operations, and the reliability and efficiency of rail freight.

“We continue to work with the UK government to fulfil our industry’s potential and this is a great example of what can be achieved when the industry and government work together effectively.”

Rail freight is already much greener than moving goods by road. Lorries emit nine times the emissions of rail freight per tonne kilometre. Shifting goods from roads to the railways is an important pillar of the Government’s Transport Decarbonisation Plan.

Seamless electrification for freight could begin to see slower, more polluting diesel trains being phased out. In 2018 the Government challenged the rail industry to remove all diesel-only trains from the network by 2040 as part of a drive to achieving the UK’s ambitious net zero goals, as well as to help improve air quality and reduce noise pollution.

The system being trialled in Northamptonshire is based on one developed by Furrer+Frey for passenger train depots, used by Eurostar and LNER, and has been installed by SPL Powerlines.

The DEFT project is one of 30 groundbreaking initiatives that have won a share of £9 million from the Department for Transport, in partnership with Innovate UK. The competition is focused on developing pioneering technology and exceptional ideas that can improve journeys for travellers, encourage passengers back onto the network and reduce the environmental impacts of rail as the country builds back better from Covid-19.

The DEFT concept was endorsed by members of the Rail Forum Midlands in 2020 as a viable method to decarbonise UK rail freight, leading to the successful funding bid to InnovateUK and the Department for Transport.

Tarmac is among the largest users of rail freight, transporting construction materials by rail UK-wide as part of the business’ ongoing sustainability commitments.