GB railfreight services

We operate efficient and dependable services across the country and beyond. Explore our wide range of services from Intermodal to bespoke rail tours, and everything in between.

With our people-focused values, our staff are primed to work directly with customers to help them realise their rail freight needs, creating a truly tailored service in every aspect of the industry.

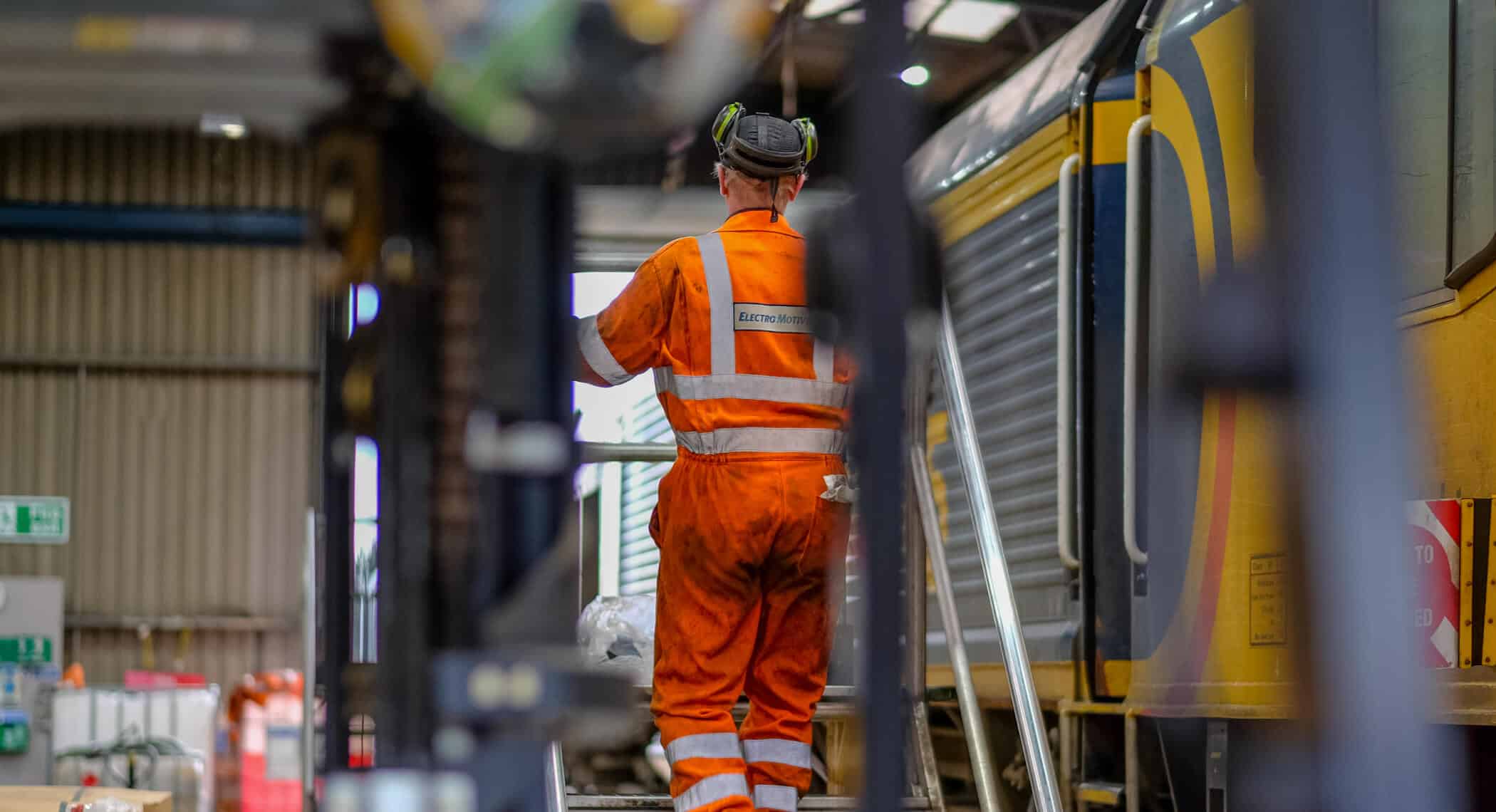

Our team tailor services to clients’ operational needs, from storage, stock movements to new vehicle testing.

Working with leading UK & European manufacturers, vehicle maintainers and passenger operators, we offer a wide range of services from new train delivery to disposal of legacy BR fleets.

With extensive knowledge in supporting new vehicle testing for Hitachi, Siemens, Alstom and CAF we offer bespoke operating packages across the country.

Our passenger portfolio includes the luxurious Belmond Royal Scotsman touring train as well as providing operational services to support the Caledonian Sleeper services for Transport for Scotland.

We operate intermodal services to and from the UK’s three largest ports, transporting around 30% of all containerised traffic.

We operate intermodal services to and from multiple ports in the UK, including Felixstowe, Southampton, London Gateway, Tilbury, Teesport and Seaforth. We also have the capability to offer special services for other ports such as Grangemouth and Port of Tyne.

The inland terminals we deliver to are Hams Hall, Birch Coppice and EMG in the midlands, Doncaster, iPort, Tinsley and Rotherham in Yorkshire, Manchester and Widnes in the North West plus Mossend in Scotland. We also have the capability to offer final mile haulage through our longstanding road haulage partners.

For further details regarding our services, to request a full copy of our timetable or to set your business up as a customer, please contact our intermodal team on 01394 613304 or by emailing intermodal.booking@gbrailfreight.com.

We move fuels for energy generation across the country.

We operated an inaugural service with Drax Power to transport Biomass and operate a fleet of bespoke wagons. This has helped to win us new customers such as Lynemouth Power. Our Biomass deliveries can move circa 115,000 tonnes per week using around 80 trains.

We also move gas condensate for the production of specialised fuels and jet fuel to Heathrow.

We provide internal logistics solutions to the UK industry.

At Celsa’s Cardiff works, we move finished, and part finished, products across their internal rail network.

Our rail logistics solutions support automotive companies by transporting vehicles in specially designed transporter wagons.

Using rail to transport large volumes reduces costs, lowers the environmental impact and simplifies the process of supply chains, allowing more flexible logistics planning. Our vision for the automotive network is to expand our portfolio by supporting the automotive components industry. Using our expertise in the movement of goods to and from Europe, we are able to offer lower unit costs for our customers, on movement, the importing of automotive parts and exported vehicles.

Our haulage of gypsum and various aggregate products enable the development of the UK’s biggest infrastructure projects. Our haulage of construction materials such as Aggregates, Gypsum & Cement is critical to the delivery of some of the UK’s major construction projects.

Through our contracts with companies like Aggregate Industries, Cemex, Day Aggregates, Heidelberg, Sibelco and Tarmac, every year we transport approximately 5 million tonnes of aggregates and sand, in addition to 600,000 tonnes of cement. We transport raw materials from import locations and power stations to processing facilities for the production of plaster and plasterboard through our EBP contract.

We also transport around 600kt of non-hazardous waste, providing an environmentally friendly alternative to road transport. Utilising the development of railheads in across the country, we deliver waste to treatment centers and landfill sites using specialised rail box wagons in collaboration with Biffa. Construction waste can be processed at rail hubs as needed before final delivery. Moreover, GBRf supports the movement of IBAA, a sustainable aggregate product for the construction industry.

Our proven track record for reliability, timely delivery, and exceptional customer care has earned us long-term contracts to provide UK-wide services for Network Rail and various industry partners.

We have been pivotal in the construction of major infrastructure projects, including the Elizabeth line, and are currently contributing to HS2. Our services have diversified to include the operation and maintenance of yellow plant machinery for the Elizabeth line, encompassing advanced equipment such as rail milling machines and self-propelled engineering trains.

We are committed to providing the UK rail industry with a fair and transparent list of costs relating to access, facilities and rail related services across the UK and Scotland.

For all access related requests, you are required to complete the GB Railfreight Access & Facilities Request Form and email to the relevant addresses listed within the document.

Select Report(s) to Download

Delivering SAFER freight with an integrated cultureand focus on our people.

Britain’s railway system is one of the safest and most extensively used rail networks in the world. Our exceptional safety performance has been achieved by highly competent people, by close cooperation between teams and companies, the adoption of advanced health and safety management systems and the effective application of technology.

Effective leadership is critical to delivering the opportunities outlined in this strategy and to developing the necessary management capabilities. We need to empower all employees, at all levels, to work together and deliver results more efficiently and effectively than would be possible in isolation.

Services

Services Breakdown

Breakdown